JET MILL FACILITY FOR WP & WDG FORMULATING

1.1 基本结构

Basic Structure

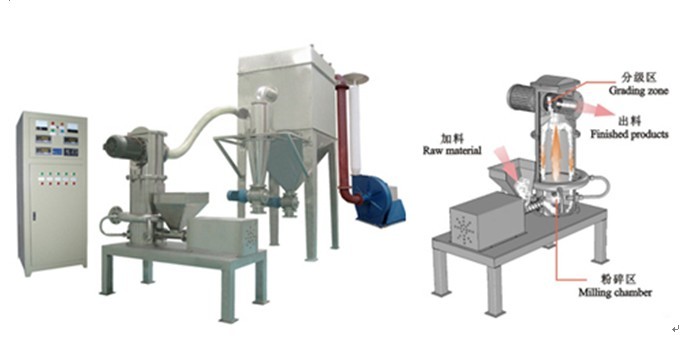

本产品是一种以压缩空气为粉碎介质的流化床气流粉碎机,磨体分为三个区,分别是粉碎区、传输区以及分级区。分级区内有分级叶轮,可由变频器调速;粉碎室有粉碎喷嘴、加料器等组成,粉碎区筒体外的环形配气盘与粉碎喷嘴相连(见图一)。

The Product is a fluidized bed pulverizer with the compressed air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the classifying area. The Classifying Area is provided with the grading wheel, and the speed can be adjusted by the inverter(VFD). The crushing room is composed of the air nozzles, feeder, etc. The ring sir supply disc outside the crushing canister is connected with the crushing nozzle (see Figure 1).

1.2 工作原理

Operational Principal

物料通过加料器进入粉碎室,压缩气体通过特殊配置的四个粉碎喷嘴向粉碎室高速喷射,物料在超音速喷射流中加速,并在粉碎室中心交汇处反复冲击、碰撞,达到粉碎。被粉碎物料随上升气流进入分级室,由于分级轮高速旋转,物料在上升的过程中,颗粒既受到分级转子产生的离心力,又受到气流粘性作用产生的向心力,当粒子受到的离心力大于向心力,即比要求的分级粒径大的粗颗粒进不了分级轮内腔返回粉碎室继续被粉碎,达到要求的分级粒径的细粒子进入分级轮内腔并随气流进旋风分离器、捕集器被收集,过滤后的气体经过喷淋处理后由引风机排出。

The material enters the crushing room through the material feeder. The compression air nozzles into the crushing room in high speed through the specially equipped four crushing nozzles. The material gains acceleration in the ultrasonic jetting flow and repeatedly impact and collide at the central converging point of the crushing room until it is crushed. The crushed material enters the grading room with the upflow. Because the grading wheels spin at high speed, when the material ascends, the particles are under the centrifugal force created from the grading rotors as well as the centripetal force created from the viscosity of the airflow. When the particles is under the centrifugal force larger than the centripetal force, the coarse particles with larger diameter than the required grading particles will not enter the inner chamber of the grading wheel and will return to the crushing room to be crushed. The fine particles that comply with the diameter of the required grading particles will enter the grading wheel and flow into the cyclone separator of the inner chamber of the grading wheel with the airflow and get collected by the collector. The filtered air is released from the air intaker after the spraying treatment.

1.3 性能特点

Performance characteristics

1.3.1 能耗少 与其他类型气流粉碎机相比节能30%~40%。

Low energy consumption: it can save 30%~40% energy compared with other air pneumatic pulverizers.

1.3.2 磨损小 由于主要粉碎作用是粒子相互冲击、碰撞,高速粒子与壁面很少碰撞,可适用粉碎莫氏九级以下物料。

Low wear: Because the crushing effect is caused by the impact and collision of particles, the high-speed particles seldom hit the wall. It is applicable to crushing the material below Moh’s Scale 9.

1.3.3 分级范围广 物料的粉碎细度可以通过调整分级轮的转速及对系统的调控进行控制其细度,一般可达到d =2~15μm。

=2~15μm。

Wide grading scope: the crushing fineness of the material can be regulated through adjusting the rotation speed of the grading wheels and the system. Generally, it can reach d =2~15μm.

=2~15μm.

1.3.4 设备结构紧凑,主机腔体内组成闭回路粉碎。

Compact structure: the chamber of the main machine composes the closes circuit for crushing.

1.3.5 操作维护方便,设备运转实现自动化。

Convenient operation and maintenance, automatic equipment operation.

1.3.6 适用于混合比大,难粉碎物料和粘性物料的粉碎。

It is applicable to crushing high mixing ratio materials difficult for crush and viscous materials.

2、主要技术参数和工艺配置

Main Technical Parameters and Process Configuration

2.1 技术参数

Technical parameter

QYF型流化床气流粉碎机主要技术参数见表1:

The main technical parameters of QYF fluidized bed pneumatic pulverizer are listed in Table 1.

表1 QYF型流化床气流粉碎机主要技术参数

Table 1 Main technical parameters of QYF fluidized bed pneumatic pulverizer

|

型 号 Model |

QYF-260 |

QYF-400 |

QYF-600 |

QYF-720 |

|

工作压力(Mpa)

Working pressure (Mpa) |

0.75~0.85 |

0.75~0.85 |

0.75~0.85 |

0.75~0.85 |

|

空气耗量(m3/min)

Air consumption (m3/min) |

6 |

10 |

20 |

40 |

|

进料粒径(目)

Diameter of fed material ( mesh) |

100~325 |

100~325 |

100~325 |

100~325 |

|

粉碎细度(d97μm)

Fineness of crushing(d97μm) |

3~15 |

3~15 |

4~15 |

5~15 |

|

生产能力(kg/h)

Capacity (kg/h) |

50~200 |

80~380 |

200~500 |

400~1000 |

|

装机功率(kw)

Installed power (kw) |

57 |

88 |

176 |

349 |

2.2 工艺配置

Process configuration

此气流粉碎机系统由空压机、储气罐、冷冻干燥机、气体过滤装置、流化床气流粉碎机主机、旋风分离器、捕集器、引风机等组成。

The pneumatic pulverizer is composed of the air compressor, gas tank, freeze dryer, air filter, fluidized bed pneumatic pulverizer, cyclone separator, collector, air intaker and others.

The process flow is showed in Figure 2: